It is suitable to be used for batching machining of auto parts

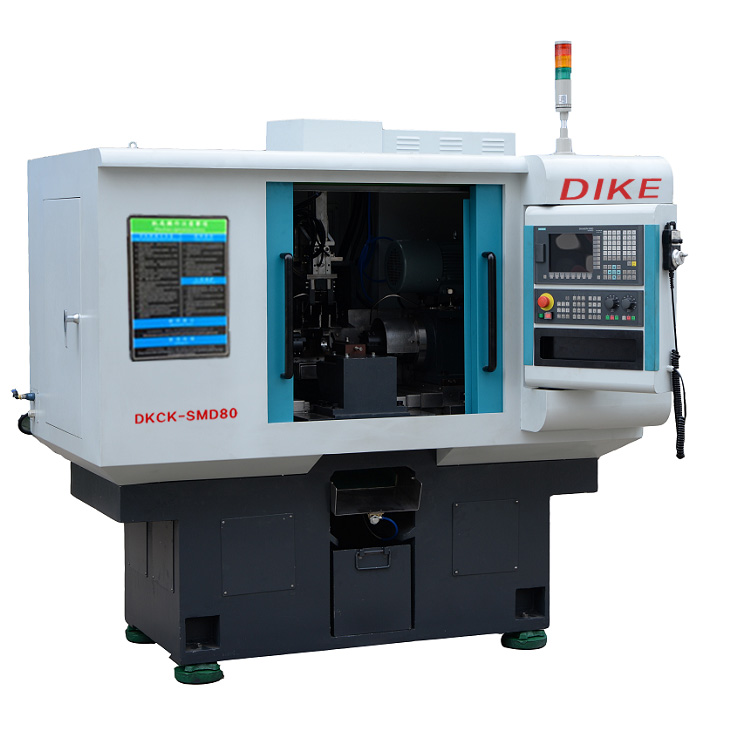

Fully automatic CNC double-head chamfering machine adopts Siemens controlling system ,with servo system control of feeding device and special changing type for blade and clamp

| Machine parameter机床参数 | ||

|---|---|---|

| item分类 | Name名称 | Parameter参数 |

| Machining range 加工能力 | Maximum clamping diameter 最大夹持直径 | φ10mm—100mm |

| Turning length 车削长度 | Customized according to parts | |

| Automatic range 自动化能力 | Automatic up loading内置上料机构 | Built-in high-speed loading |

| Automatic down loading内置收料机构 | Built-in high-speed unloading | |

| Composition 硬件设施 | Maximum stroke X/Z机床最大行程X/Z | 150/150mm |

| Fast move speed X/Z快速移动速度X/Z | 20m/min | |

| Spindle motor power主轴电机功率 | 2.2KW-servo motor伺服电机(ALPHA) | |

| Spindle 主轴 | Customized high precision spindle unit | |

| Spindle RPM主轴 | 1500r/min无极变速 | |

| Ball screw丝杆 | Hiwin, Taiwan, China台湾上银 | |

| Linear guider导轨 | Hiwin, Taiwan, China台湾上银 | |

| Electricity parts 电器控制 | Electricity parts电器元件 | Schneider 施耐德 |

| Control system控制系统 | Siemens808D | |

| Driving type 驱动类型 | 6N*M(X/Z)Servo motor伺服电机 | |

Machine Composition

Machining Cases

Machining Cases

On-Site Show