DKCK-M5系列数控车床,斜床身设计!集合大马力,快速加工,高效率高刚性结构,在车削锻件零件中有优异的表现,轴承套圈加工,复杂型圈类、套类、轴类盘类零件的理想选择。

| Item 分类 | Name 名称 | Parameter 参数 |

| Machining range 加工能力 | Max. rotating diameter 最大回转直径 | Ø450mm |

| Maximum clamping diameter 最大夹持直径 | Ø150mm | |

| Automatic range 自动化能力 | Automatic Uploading 内置上料机构 | M5 Built-in high speed uploading mechanism |

| Automatic Downloading 内置收料机构 | M5Built-in high speed downloading mechanism | |

| Composition 硬件设施 | Maximum stroke X/Z 机床最大行程X/Z | 350/250mm |

| Fast move speed X/Z 快速移动速度X/Z | 20m/min | |

| Automatic Clamp 自动化夹具 | Dike Research |

|

| Spindle motor power 主轴电机功率 | 7.5KW servo motor | |

| Spindle 主轴 | M5 special made high precision spindle unit | |

| Spindle RPM 主轴转速 | 3000r/min stepless speed change | |

| ball screw/Linear guider 丝杆/导轨 | Hiwin/PMI, Taiwan | |

| Machine structure 床身 | High quality Casting | |

| Electricity parts 电器控制 | Electricity parts 电器元件 | Schneider |

| Control system 控制系统 | Siemens 808D | |

| Driving type 驱动类型 | Servo motor 10N*M (X/Z) | |

| Overall size 外形尺寸 | Overall size 外形尺寸 | 2000X1500X1700 |

| net weight 机床净重 | 3.5T |

| 2、轴承套圈加工精度(单位mm) | |||

|---|---|---|---|

| 内圈 | 外圈 | ||

| 项目 | 标准 | 项目 | 标准 |

| 直径尺寸重复定位误差 | <0.02 | 直径尺寸重复定位误差 | <0.02 |

| 壁厚差 | <0.02 | 壁厚差 | <0.02 |

| 圆度误差 | <0.02 | 圆度误差 | <0.02 |

| 防尘槽高度重复定位误差 | <±0.02 | 防尘槽高度重复定位误差 | <±0.02 |

| 粗糙度 | ≤1.6 | 粗糙度 | ≤1.6 |

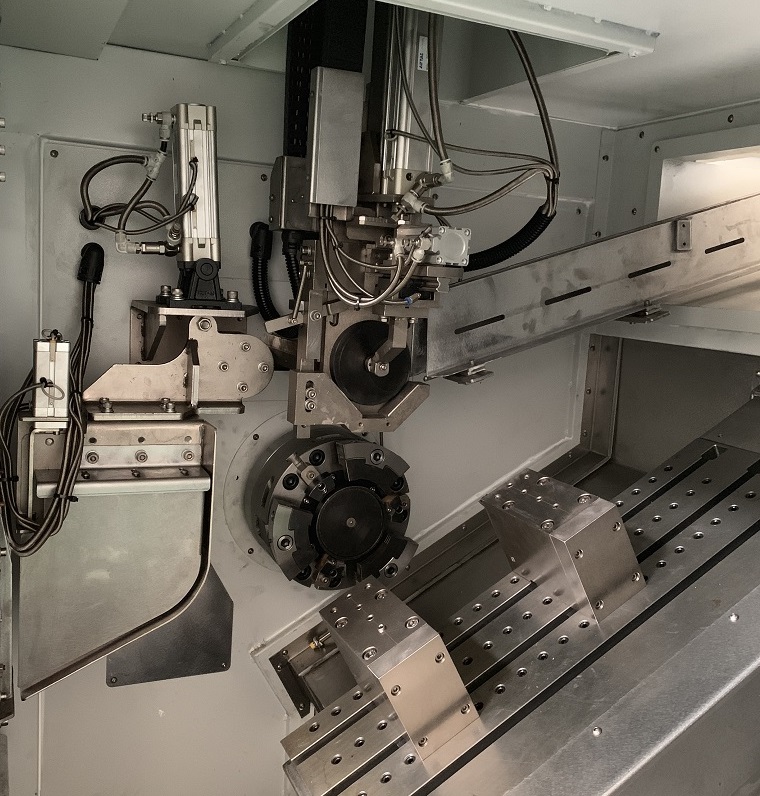

机床配置

连线方案

DKCK-M5 提升式自动上料三连线

2台机器连线,通过提升式上料机实现高生产率的装卸、夹紧和加工,特别适合批量生产。

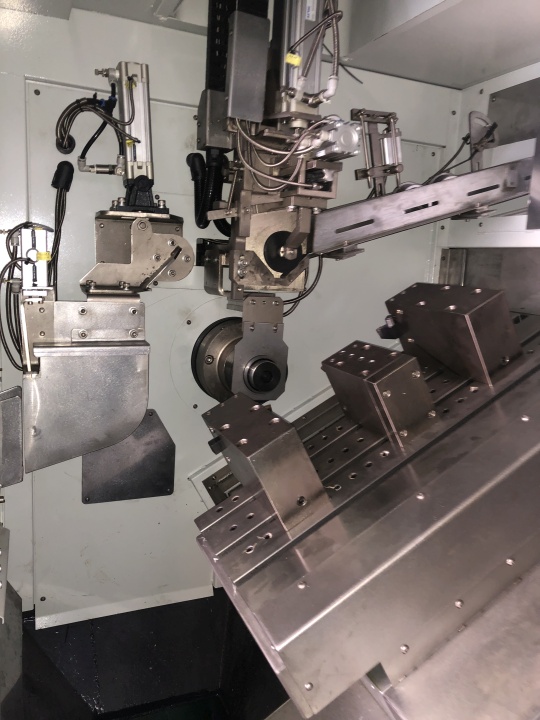

加工案例

现场展示