Double spindle CNC lathe(DKCK-ST80)

DKCK-ST80 double-spindle CNC lathe,equals two sets of high precision CNC lathes,combined with automatic loading and unloading conveyor.It occupies less working space,avoids workpiece injury,saves energy,has high efficiency etc.

| Name 名称 | Parameter参数 | Name 名称 | Parameter 参数 |

|---|---|---|---|

| 最大回转直径 Max. rotating diameter |

Ø300mm | 车铣动力头 Power head(turning & milling) |

Optional选配 |

| 最大夹持直径 Max. clamping diameter |

Ø72mm | 主轴跳动 Spindle runout |

<0.005mm |

| 可加工工件长度 Workpiece length |

80mm | 定位精度 Position precision |

<0.005mm |

| X向行程 X axis stroke |

500mm | 重复定位精度 Repeat precision |

<0.003mm |

| Z向行程 Z axis stroke |

250mm | 排刀架方柄刀座 Square tool holder |

20x20 |

| 主电机功率 Main motor output |

5.5~15KW | 排刀架圆孔刀座 Round tool holder |

Ø20 |

| 主轴最高转速 Max. spindle speed |

3000~8000 RPM | 外形尺寸 Overall |

2900*1700*1900 |

| 数控系统 CNC system |

Siemens 808D/828D | 重量 Weight |

4.5T |

Machine configuration

Connection plan

双主轴带自动检测机,在线检测,刀具实时补偿

Double spindle with automatic detector, online detection, tool real-time

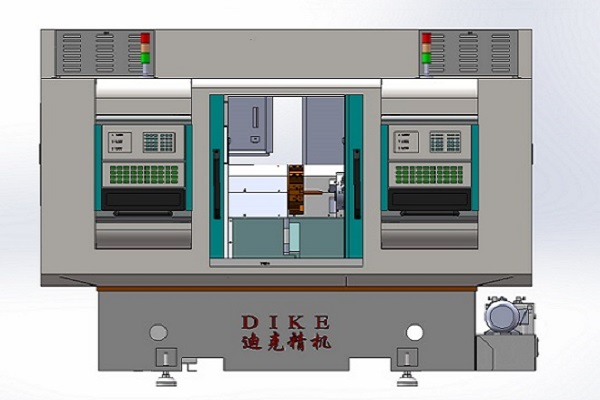

双主轴带刀塔正面图

Double spindle with turret front view

双主轴带刀塔俯视图

Double spindle with turret top view

machineing case

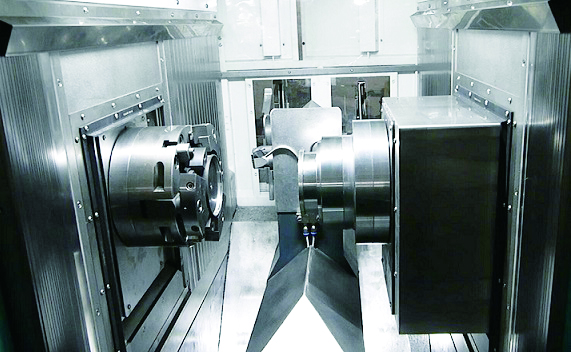

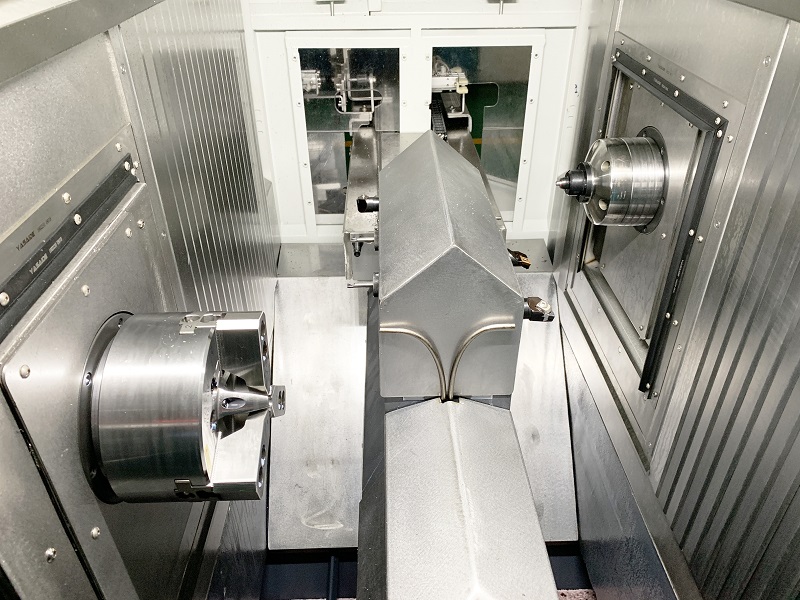

On-site Show