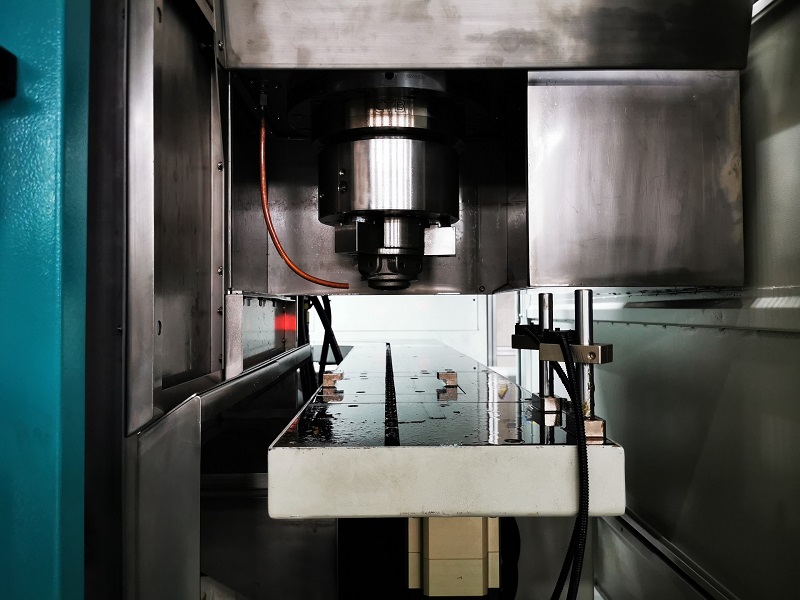

The DL5 vertical turning center is able to machine workpieces having a maximum diameter of up to 300 mm. The DL5 is one of DIKE's modular turning centers that stand out by their very compact design.The DL5 also features an integrated pick-up automation system.

1.Highest productivity due to short distances.

2.Minimal space requirements owing to compact design of vertical turning centers.

3.Full automation: the machines load themselves using the pick-up spindle, the raw and finished parts storage is included.

4.The 12-post tool turret (also for driven tools) features very short indexing times.

5.All serviceable units are freely accessible and thus easy to reach.

6.The machine base made from polymer concrete ensures high stability and outstanding vibration damping.

7.Vertical machining guarantees optimal chip flow.

8.With the addition of a Y-axis in the turret, the machine tools can be equipped to machine complex geometries.

9.The VL series turning centers can also be easily interlinked. The automation of the line is thus tailored to the customer’s preference It's very easy to interlink several machines.