适用于汽车零部件,轴承套圈加工,复杂型轴类和套类工件的加工。

| 1、主要技术参数 | |||

|---|---|---|---|

| 项目 | 单位 | 参数 | |

| 加工范围 | 最大回转直径 | mm | Ø280 |

| 最大夹持直径 | mm | Ø72 | |

| 车削长度 | mm | 80 | |

| 通孔直径 | mm | Ø46 | |

| 主轴电机 | 输出功率 | kw | 4KW伺服电机(可选) |

| 最高转速 | r/min | 3000 | |

| 液压泵 | 输出功率 | kw | 1.5 |

| 拖板最大行程 | Z轴 | mm | 200 |

| X轴 | mm | 300 | |

| 设备精度 | 径向跳动 | mm | <0.01 |

| 轴向跳动 | mm | <0.01 | |

| 定位精度 | mm | 0.003~0.005 | |

| 重复定位精度 | mm | 0.002~0.004 | |

| 设备外形尺寸(长宽高) | mm | 2200*1600*2000 | |

| 设备净重 | kg | 1700 | |

| 气动原件 | 亚德客 | ||

| 导轨 | 直线导轨(台湾上赢) | ||

| 丝杆 | 滚珠丝杠(台湾上赢) | ||

| 控制系统 | 西门子808D | ||

| 驱动类型 | 伺服电机 | ||

| 电器元件 | 施耐德(法国) | ||

| 主轴 | 主轴单元(HRB轴承) | ||

| 2、轴承套圈加工精度(单位mm) | |||

|---|---|---|---|

| 内圈 | 外圈 | ||

| 项目 | 标准 | 项目 | 标准 |

| 直径尺寸重复定位误差 | <0.02 | 直径尺寸重复定位误差 | <0.02 |

| 壁厚差 | <0.02 | 壁厚差 | <0.02 |

| 圆度误差 | <0.02 | 圆度误差 | <0.02 |

| 防尘槽高度重复定位误差 | <±0.02 | 防尘槽高度重复定位误差 | <±0.02 |

| 粗糙度 | ≤1.6 | 粗糙度 | ≤1.6 |

机床配置

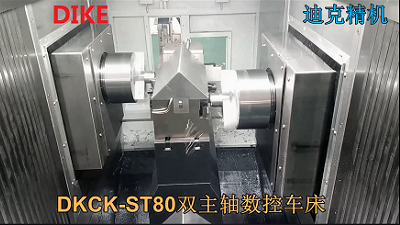

床身采用迪克平床身车床

驱动类型:伺服电机

主轴转速:3000r/min

加工范围:直径30-100mm,长度5-80mm

最大行程:X:300mm,Z:200mm

主电机功率:4KW伺服电机(可选)

布局形式:整体铸件平床身

机床尺寸:1700*1130*1700mm(长x宽x高)

机床净重:1.7T

采用HIWIN高精密研磨级滚珠丝杠

高效率及可逆性、零背隙及高刚性、高导程精度寿命可预测、低起动扭矩及顺畅度、静音短交期优于气液压致动器的优点

配合HIWIN高精密滚珠式直线导轨

线轨为四列式单圆弧牙型接触直线导轨,同时整合优化结构设计的重负荷精密直线导轨,相较于其他之直线导轨提升了负荷与刚性能力。 具备四方向等负载特色、及自动调心的功能,可吸收安装面的装配误差,得到高精度的诉求。基于高速度、高负荷、高刚性与高精度研发。

SIEMENS 808D数控系统

SINUMERIK 808D 车削符合现代普及型车床的所有要求:高轮廓精度和高动态特性,确保了最高的机床生产效率

适合于车削加工应用:

- 一个加工通道中最多 4 进给轴/ 主轴

- 专为斜床身和平床身数控车床定制的系统软件

多种上下料方式可选

连线方案

配合迪克圆盘式自动上料机和连线装置可实现全自动生产线。

加工案例

现场展示